Application research on dynamic calibration and prediction technology of coal seam in coalmine working face

-

摘要: 智能开采对于地质条件的不适应问题非常突出,特别是对煤层起伏和厚度的绝对精度提出了更高的要求。三维地震勘探横向分辨率高,能够对煤层起伏进行控制,但在地震解释时,煤层底板高程受时深转换计算影响,存在一定的误差。针对这一问题,以工作面三维地震数据和采掘过程中探煤厚数据为基础,通过不断更新速度场提高煤层底板时深转换绝对精度;同时利用迭代插值算法,不断更新工作面煤层厚度;通过对计算得到的数据进行误差统计和分析。在TJH304回采工作面进行试验,利用工作面巷道和切眼探煤厚数据并结合三维地震资料动态解释后,工作面推采前方煤层底板高程值和厚度值绝对误差变小;特别是距离当前采煤面30 m以内的4个验证点煤层底板高程值误差范围为0.37~0.58 m,煤层厚度值误差为0.32~0.44 m。结果表明,三维地震动态解释技术可最大化将三维地震和井下生产数据有效结合,不断提高煤层空间精度,为智能开采提供预想煤层模型。Abstract: One of the prominent problems of intelligent mining is its inadaptability to geological conditions, especially for the absolute accuracy of coal seam floor and thickness. 3D seismic has a high horizontal resolution and it can control the ups and downs of the coal seam. However, due to the time domain data, the calculation of the coal seam floor elevation is negatively affected by the time-depth conversion point. On the basis of the 3D seismic data of the working face and the coal thickness data during the mining process, the absolute accuracy of the time-depth conversion of the coal seam floor is improved by continuously refreshing the velocity field. At the same time, the iterative interpolation algorithm is used to continuously update the coal seam thickness of the working face, then error statistics and analysis are conducted based on the calculated data. The experiment was carried out at TJH304 working face after using coal seam floor height and thickness of working face tunnel and mining face combined with the dynamic interpretation of the 3D seismic data. The absolute error of the coal seam floor elevation and thickness values in front of the working face is reduced. In particular, the four verification points within thirty meters from the current mining face and the coal seam floor elevation error is between 0.37-0.58 m; the coal seam thickness error is between 0.32-0.44 m. The results show that the 3D seismic dynamic interpretation technology can maximize the effective combination of 3D seismic and downhole production data, continuously improve the spatial accuracy of coal seam, and provide a prospective coal seam model for intelligent mining.

-

我国煤矿智能化开采基本上实现了从单机自动化向“三机”协同自动化以至于局部系统智能化的技术跨越[1-2],但智能开采对于复杂地质条件的适应性远远不足[3],究其原因,一是煤矿开采重型装备的自动化与智能化水平、远程控制系统的自主决策能力有待提高[4];二是工作面基础地质条件查明精度不足,导致智能开采遭遇地质条件较大变化时无法迅速调整适应等[5]。

智能化开采对煤层厚度、煤层起伏形态提出了更高的精度要求[6]。构建高精度三维地质模型成为实现智能化的关键技术问题之一[7]。由于工作面内部已知数据较少,采用传统的插值算法无法有效预测工作面煤层起伏。三维地震勘探能够对煤层起伏、埋深、厚度和构造等进行高精度探测[8-10],但由于其标定数据的稀缺性,导致反演得到的煤层底板精度受限[11]。回采工作面两侧巷道具有大量的探煤厚数据,同时随着切眼不断推进,会不断产生探煤厚数据,利用这些数据对三维地震进行动态解释和标定,可不断提高煤层底板反演的精度,从而从根本上提高地质建模精度。同时煤层厚度较为稳定的工作面,可通过插值算法迭代更新煤厚不断降低预测误差[12]。

前人对三维地震勘探技术开展了大量的研究工作,但是对于面向智能化开采的地震动态解释技术还没有进行系统的研究。本文以三维地震数据为基础,利用回采工作面巷道和切眼得到的探煤厚数据,重新标定三维地震数据,更新平均速度场,更新回采工作面煤层底板模型,同时采用离散光滑插值不断迭代工作面煤层厚度,利用假设的未回采处探煤厚数据进行精度对比,研究更新过程中精度变化及存在的问题。

1 三维地震动态解释原理

三维地震动态解释是在常规的地质分析、反射波标定、波组对比、层位构造解释的基础上进行的,由于矿井在采掘过程中可不断得到煤层顶底的空间坐标,从而能够对该煤层的底板反射波和煤层厚度进行重新标定校正。

工作面煤层底板反射波为密度较高的网格化数据,若其采集处理方法得当,其成果精度能够控制煤层起伏。由于反射波记录为时间域数据,需要利用已知煤层底板高程值构建速度场,进行时深转换。由于煤田声波测井资料稀缺,常采用平均速度场方法,其精度主要受标定点的密度和均匀度影响。

计算标定点处的速度值公式为:

$$ v\left(i\right)=2\times (H-{W}_{{\rm{b}}}\left(i\right))/t\left(i\right) $$ (1) 式中:

$ v\left(i\right) $ 为第$ i $ 个标定点处平均速度;$ {W}_{{\rm{b}}}\left(i\right) $ 为第$ i $ 个标定点处煤层底板高程;$ t\left(i\right) $ 为第$ i $ 个标定点处煤层底板反射波双程旅行时;$ H $ 为地震数据处理基准面。对所有标定点计算得到的速度值进行内插,得到平均速度网格数据

$ v\left({i},{j}\right) $ ,按照时深转换公式可计算出目标层位底板高程:$$ {W}_{{\rm{b}}}\left(i,j\right)=H-v\left(i,j\right)\times t(i,j) $$ (2) 式中:

$ H $ 为三维地震处理基准面;$ v\left(i,j\right) $ 为第$ \left(i,j\right) $ 个内插点的速度;$ t(i,j) $ 为第$ \left(i,j\right) $ 个解释点处目标层反射波地震双程旅行时;$ {W}_{{\rm{b}}}\left(i,j\right) $ 为第$ \left(i,j\right) $ 个点目标层煤层底板高程。采用离散光滑插值算法,不断融合采掘揭露的数据,更新工作面煤厚值。离散光滑插值是一种无维数的内插方法,它不以空间坐标为参数,主要依赖于网格结点的拓扑关系,通过使网格点满足特定约束条件,求解一个线性方程得到未知结点上的值[13]。

首先建立网格结点

$ \varphi $ 最优解目标函数:$$ {R}^{*}\left(\varphi \right)=R\left(\varphi \right)+\rho \left(\varphi \right) $$ (3) 式中:

$ R\left(\varphi \right) $ 为全局粗糙度函数;$ \rho \left(\varphi \right) $ 为线性约束违反度函数,其约束点为插值点。使式(3)无限逼近最小值,达到

$ \varphi $ 在任意结点的函数值逼近该点领域结点$ \varphi $ 值的均值,使插值点处的结点的预测值尽可能逼近插值数据。通过求解全局粗糙度函数使网格结点尽可能平滑:

$$ R\left(\varphi \right)=\displaystyle\sum\nolimits _{k}^{\varOmega }\left\{\mu \left(k\right){\left|\displaystyle\sum\nolimits _{a}^{\mathrm{\Lambda }\left(k\right)}{v}_{a}\left(k\right)\varphi \left(a\right)\right|}^{2}\right\} $$ (4) 式中:

$ \mu \left(k\right) $ 为在结点$ k\in \varOmega $ 上的权系数,可调整局部光滑度;$ a $ 为$ \mathrm{\Lambda }\left(k\right) $ 的结点;$ \mathrm{\Lambda }\left(k\right) $ 为结点k邻域内不包含k的结点的集合;$ {v}_{a}\left(k\right) $ 为在结点k的邻域内结点$ a $ 的权系数;$ \varphi \left(a\right) $ 为结点$ a $ 处的真实值。通过违反度函数进行结点约束:

$$ \rho \left(\varphi \right)=\displaystyle\sum\nolimits _{a}^{\varOmega }\displaystyle\sum\nolimits _{i}^{M}{\tilde {\omega }}_{i}^{2}{\left|{A}_{i}\left(a\right)\varphi \left(a\right)-{b}_{i}\left(a\right)\right|}^{2} $$ (5) 式中:

$ a\in \varOmega $ ;$ {\tilde {\omega }}_{i}^{2} $ 为给定的正数,$ {A}_{i}\left(a\right)\varphi \left(a\right)-{b}_{i}\left(a\right) $ 为结点$ a $ 关于$ \varphi $ 的第$ i $ 个结点的线性约束;M为结点数量;$ {A}_{i}\left(a\right) $ 和$ {b}_{i}\left(a\right) $ 为给定常数。具体插值步骤如下。

① 准备散点数据的三维空间坐标(x,y,z)。

② 以散点数据的平面坐标为边界范围,构建平面网格,网格间距分别为dx和dy,网格点初始纵向坐标值取所有散点数据z值的平均值。

③ 设置插值约束条件为:已知点之间曲率最小、已知点处的解算值小于设置的阈值;通过插值算法迭代求解各网格节点处的z值。

④ 将网格之间进行填充可视化。

2 三维地震动态解释实例

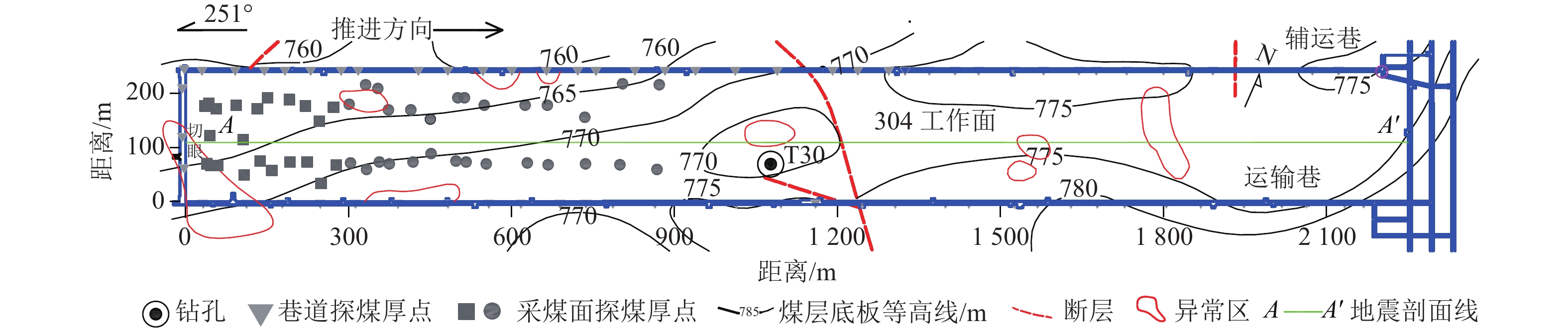

本次试验工作面为TJH304工作面,主采6号煤层,煤层埋深为469.7~533.1 m,煤层厚度为11.6~17.5 m,煤层倾角为0~6°,煤层整体为一单斜构造,呈东南高西北低,局部有褶曲。工作面倾向长度为240 m,走向长度为2141 m,工作面辅运巷、运输巷和切眼共有72个探煤厚点,工作面内部有1个钻孔,采煤面共有44个探煤厚点(图1)。

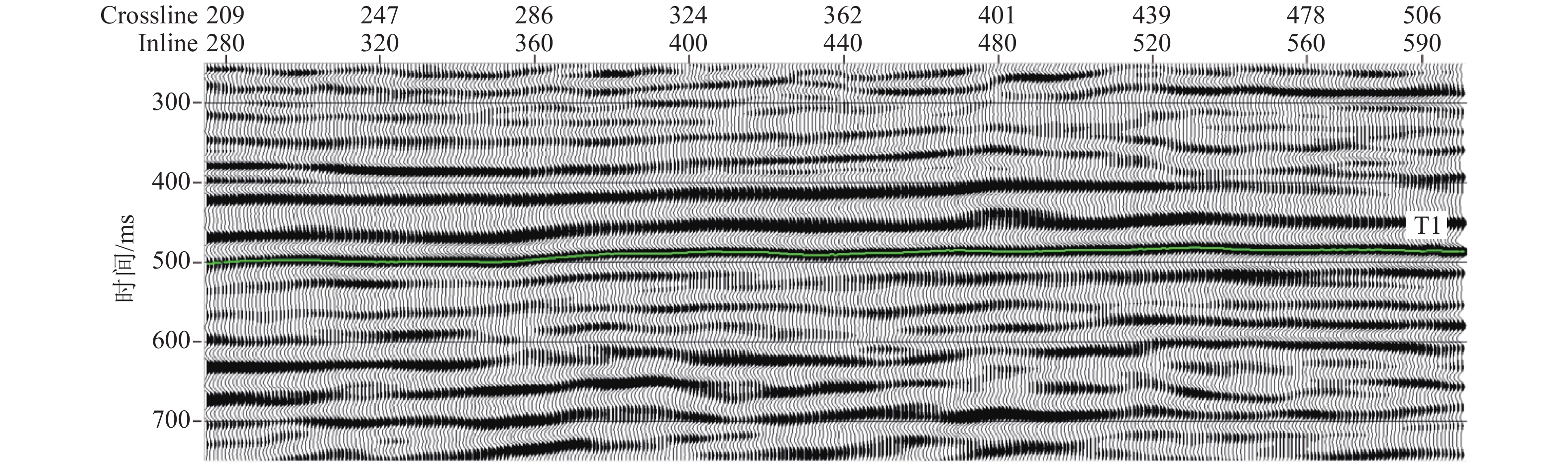

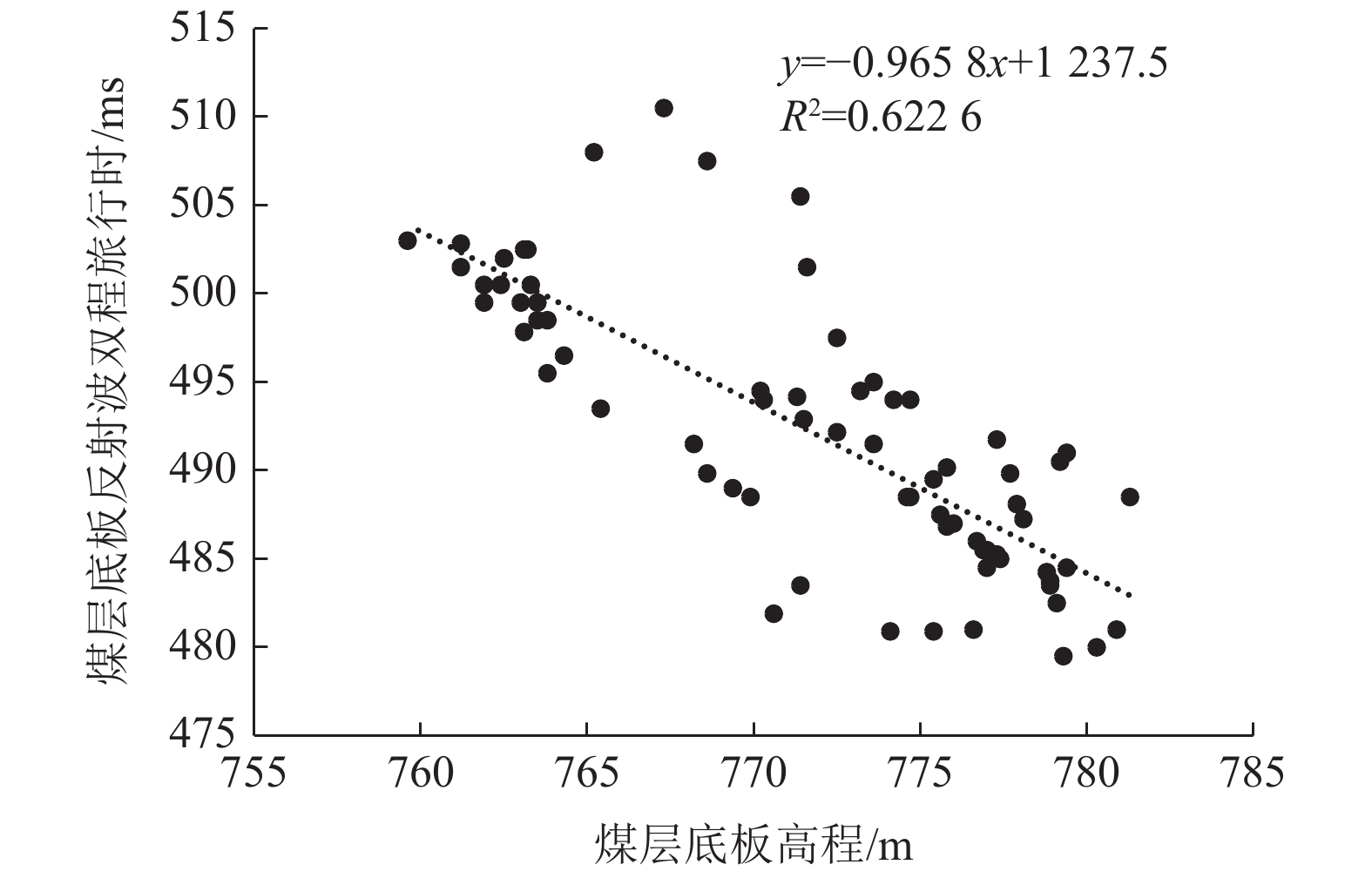

三维地震数据覆盖工作面全区,CDP网格5 m×5 m,覆盖次数80次。图2为工作面推进方向地震剖面,图中T1层位为6号煤层底板反射波,反射波能量强、信噪比高,煤层局部有起伏。图3为运输巷、辅运巷和切眼探煤后得到的6号煤层底板高程和其对应的双程旅行时交会图,两者相关性可达62.26%。相关性较好时,说明平均速度变化不大,采用平均速度法进行时深转换比较稳定,可作为检验数据质量的一个判断准则。当煤层上覆地层存在速度异常体或较大的横向速度变化时,该处平均速度出现突变,会对时深转换精度影响较大。

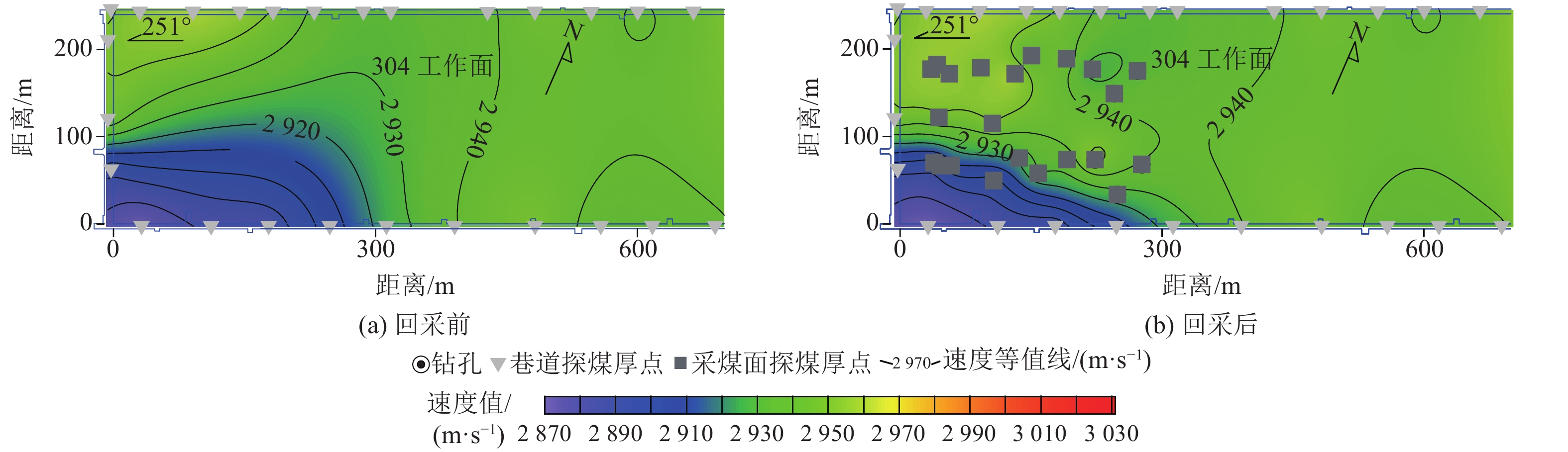

在工作面形成后,还未开采前,利用辅运巷、运输巷和切眼得到的煤层底板高程作为新的时深转换标定点,对T1反射层位平均速度场进行更新(图4a),时深转换得到新的6号煤层底板高程数据,利用工作面开采后回采面获得的煤层底板高程,对验证点处更新前后高程误差进行统计分析;在工作面开始回采后,分别选取回采进尺300 m和329 m以内的探煤厚数据,继续更新T1反射层位平均速度场(图4b),更新6号煤层底板高程数据,分别利用回采进尺300 m和329 m以后的探煤厚点验证点,对更新前后高程误差进行统计分析。

同理,对于煤层厚度,采用以上过程,利用离散光滑插值对6号煤层厚度数据迭代更新(图5),并进行误差统计分析。

由图4可知,平均速度场由于采煤面标定点的增多,在0~300 m范围速度变化更加精细。由图5可知,煤层厚度由于采煤面厚度点的增多,在0~300 m范围煤层厚度变化更加明显。

3 面向智能开采的解释精度分析

基于三维地震解释成果和探煤厚数据开展回采工作面煤层底板和厚度动态预测,其精度主要受以下因素影响:地表障碍物、复杂地表、表浅层地层非均质性影响,地层速度异常、速度横向突变,煤层局部起伏较大,煤层厚度局部变化较大,探煤厚点数量等因素。

表1为不同开采阶段煤层底板与煤层厚度预测绝对误差统计。可以看出在回采前,利用速度场刷新和煤厚迭代插值,煤层底板绝对误差可控制在0.42~3.63 m,与常规三维地震解释精度相比具有较大提高,煤层厚度误差可控制在0.27~1.89 m内。在进入回采后300 m处,利用速度场刷新和煤厚迭代插值,煤层底板绝对误差可控制在0.34~3.26 m,煤层厚度误差可控制在0.11~1.76 m内;在回采标定点最前方30 m和29 m处的4个验证点,煤层底板高程误差范围为0.37~0.58 m,煤层厚度误差范围为0.32~0.44 m。

表 1 不同开采阶段煤层底板与煤层厚度预测绝对误差Table 1. Absolute error of the prediction of coal seam floor elevation and thickness in different mining stages开采

阶段预测目标 验证点数 绝对误差

范围/m平均误

差/m0~0.5 m误差验证

点数及概率/%0.5~1.0 m误差验证

点数及概率/%大于1.0 m误差验证

点数及概率/%回采前 煤层底板 44 0.42~3.63 2.34 8/18.2 13/29.5 23/52.3 煤层厚度 44 0.27~1.89 1.32 11/25.0 13/29.5 20/45.5 回采300 m 煤层底板 22 0.34~3.26 2.12 5/22.7 7/36.4 10/45.5 煤层厚度 22 0.11~1.76 1.13 6/27.3 7/31.8 9/40.9 4 结 论

a. 三维地震数据虽然对煤层起伏能够进行较好控制,但三维地震反射波层位解释精度受数据采集、处理和时深标定点的影响较大。面向智能开采的地震动态解释技术必须在全过程进行方案设计和质量把控。

b. 针对TJH304回采工作面试验研究,通过融合采掘得到的探煤厚数据与三维地震解释成果,可提高回采工作面内部煤层底板高程和煤层厚度精度,对于已知标定点前方30 m内,煤层底板高程预测误差可达到0.58 m以下,煤层厚度值预测误差可达到0.44 m以下。

c. 由于巷道实测点分布不均、整体偏少,会对速度场更新和煤厚迭代插值造成影响,可采取缩小点距,按照固定间距采样标定点。

d. 智能化开采对于煤岩界面绝对精度要求极高,单纯通过一种技术方法不能完全解决,需结合更先进的孔中物探技术,增加工作面内部高精度点数据,同时用于地震数据标定,将工作面内部进行综合透明化。

-

表 1 不同开采阶段煤层底板与煤层厚度预测绝对误差

Table 1 Absolute error of the prediction of coal seam floor elevation and thickness in different mining stages

开采

阶段预测目标 验证点数 绝对误差

范围/m平均误

差/m0~0.5 m误差验证

点数及概率/%0.5~1.0 m误差验证

点数及概率/%大于1.0 m误差验证

点数及概率/%回采前 煤层底板 44 0.42~3.63 2.34 8/18.2 13/29.5 23/52.3 煤层厚度 44 0.27~1.89 1.32 11/25.0 13/29.5 20/45.5 回采300 m 煤层底板 22 0.34~3.26 2.12 5/22.7 7/36.4 10/45.5 煤层厚度 22 0.11~1.76 1.13 6/27.3 7/31.8 9/40.9 -

[1] 王国法,刘峰,庞义辉,等. 煤矿智能化–煤炭工业高质量发展的核心技术支撑[J]. 煤炭学报,2019,44(2):349−357. WANG Guofa,LIU Feng,PANG Yihui,et al. Coal mine intellectualization:The core technology of high quality development[J]. Journal of China Coal Society,2019,44(2):349−357.

[2] 王国法,刘峰,孟祥军,等. 煤矿智能化(初级阶段)研究与实践[J]. 煤炭科学技术,2019,47(8):1−36. WANG Guofa,LIU Feng,MENG Xiangjun,et al. Research and practice on intelligent coal mine construction(primary stage)[J]. Coal Science and Technology,2019,47(8):1−36.

[3] 程建远,朱梦博,王云宏,等. 煤炭智能精准开采工作面地质模型梯级构建及其关键技术[J]. 煤炭学报,2019,44(8):2285−2295. CHENG Jianyuan,ZHU Mengbo,WANG Yunhong,et al. Cascade construction of geological model of longwall panel for intelligent precision coal mining and its key technology[J]. Journal of China Coal Society,2019,44(8):2285−2295.

[4] 徐志鹏.采煤机自适应截割关键技术研究[D].徐州: 中国矿业大学, 2011. XU Zhipeng.Study on the key technologies of self–adaptive cutting for shearer[D].Xuzhou: China University of Mining and Technology, 2011.

[5] 王铁军.基于动态精细建模的薄煤层采煤机广义记忆切割技术研究[D].北京: 中国矿业大学(北京), 2013. WANG Tiejun.Research on the generalized memory cutting technology of thin seam shearers based on dynamic fine modeling[D].Beijing: China University of Mining and Technology(Beijing), 2013.

[6] 袁亮,张平松. 煤炭精准开采地质保障技术的发展现状及展望[J]. 煤炭学报,2019,44(8):2277−2284. YUAN Liang,ZHANG Pingsong. Development status and prospect of geological guarantee technology for precise coal mining[J]. Journal of China Coal Society,2019,44(8):2277−2284.

[7] 袁亮. 我国煤炭工业高质量发展面临的挑战与对策[J]. 中国煤炭,2020,46(1):6−12. YUAN Liang. Challenges and countermeasures for high quality development of China’s coal industry[J]. China Coal,2020,46(1):6−12.

[8] 程建远,聂爱兰,张鹏. 煤炭物探技术的主要进展及发展趋势[J]. 煤田地质与勘探,2016,44(6):136−141. DOI: 10.3969/j.issn.1001-1986.2016.06.025 CHENG Jianyuan,NIE Ailan,ZHANG Peng. Outstanding progress and development trend of coal geophysics[J]. Coal Geology & Exploration,2016,44(6):136−141. DOI: 10.3969/j.issn.1001-1986.2016.06.025

[9] 程建远,王寿全,宋国龙. 地震勘探技术的新进展与前景展望[J]. 煤田地质与勘探,2009,37(2):55−58. DOI: 10.3969/j.issn.1001-1986.2009.02.015 CHENG Jianyuan,WANG Shouquan,SONG Guolong. The new development and foreground expectation of seismic exploration[J]. Coal Geology & Exploration,2009,37(2):55−58. DOI: 10.3969/j.issn.1001-1986.2009.02.015

[10] 陆自清. 基于边界元方法的次级断裂信息挖掘试验研究[J]. 煤田地质与勘探,2020,48(5):211−217. DOI: 10.3969/j.issn.1001-1986.2020.05.026 LU Ziqing. Experiment of secondary fault information mining based on boundary element method[J]. Coal Geology & Exploration,2020,48(5):211−217. DOI: 10.3969/j.issn.1001-1986.2020.05.026

[11] 刘再斌,刘程,刘文明,等. 透明工作面多属性动态建模技术研究[J]. 煤炭学报,2020,45(7):2628−2635. LIU Zaibin,LIU Cheng,LIU Wenming,et al. Study on multi−attribute dynamic modeling technique for transparent working face[J]. Journal of China Coal Society,2020,45(7):2628−2635.

[12] 程建远,朱梦博,崔伟雄,等. 回采工作面递进式煤厚动态预测试验研究[J]. 煤炭科学技术,2019,47(1):237−244. CHENG Jianyuan,ZHU Mengbo,CUI Weixiong,et al. Experimental study of coal thickness progressive prediction in working face[J]. Coal Science and Technology,2019,47(1):237−244.

[13] LEVY B,MALLET J L. Discrete smooth interpolation: Constrained discrete fairing for arbitrary meshes[J]. Computer Aided Design,1992,24(4):263−270.

-

期刊类型引用(6)

1. 田小超,姜旭,闫文超. 钻孔组合式多参数测量仪探管结构设计. 煤矿机械. 2024(02): 103-105 .  百度学术

百度学术

2. 李蔚林,赵嘉良,阮柳谭,李泽荃. 基于空间自回归插值方法的煤层厚度预测研究. 煤炭工程. 2024(S1): 112-119 .  百度学术

百度学术

3. 赵俊杰,赵明军,张铁聪,贾瑞杰,刘兴伟. 综合物探技术在工作面高精度地质建模中的研究与应用. 中国煤炭. 2023(07): 89-101 .  百度学术

百度学术

4. 刘飞跃,杨科,杨天鸿,阚磊,付凯. 考虑煤厚煤质变异性的煤层价值模型构建与应用. 煤田地质与勘探. 2023(07): 72-79 .  本站查看

本站查看

5. 李鹏,程建远. 采掘工作面地质信息数字孪生技术. 煤田地质与勘探. 2022(11): 174-186 .  本站查看

本站查看

6. 王惠风,符超,李果,陈同俊. 大倾角煤层时深转换精度分析及改进方法. 煤田地质与勘探. 2022(10): 145-150 .  本站查看

本站查看

其他类型引用(1)

下载:

下载: